About Vacuum Continuous Soap Drying Plant

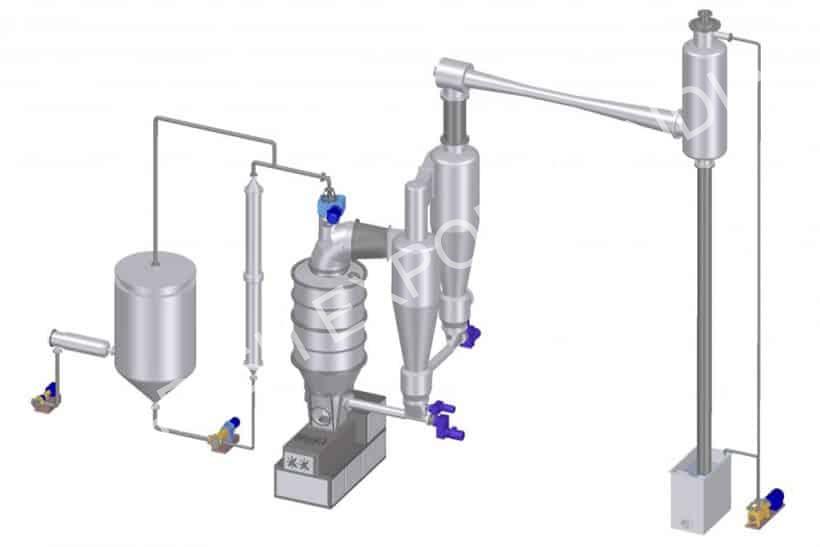

“Jagdish” vacuum driers are built in series for different capacities. The process of vacuum drying is shown in the flow chart. The base soap resulting from saponification is pumped in to the drier continuously by speed regulation of the proportioning pump. The pumps are especially suited for viscous mediums and easy to maintain.

The heat exchangers are designed for a proper heating steam pressure and a feeding temperature. They are reconciled to the special demands of soap drying where the evaporation of water already starts in the heat exchanger.

In the evacuated spraying chamber the soap is cooled down to the boiling temperature of vapor corresponding to the vacuum and sprayed on the inside wall of the chamber by means of a rotating spraying shaft with spraying nozzle. The sprayed soap is removed from the inside wall of the chamber by scraping knives being fastened at the spraying shaft. In order to produce a perfect soap quality without over dried soap particles, the inner face of the spraying chamber is made exactly. Thus, a safe and maintenance-free removal of the dried soap is possible by means of springy scrapers.

The vacuum-tight discharge of the soap out of the spraying chamber is effected by means of a noodle plodder. Driers for laundry soap usually discharge in form of a soap bar by means of a vacuum plodder. A control of the spraying chamber can be made through the above mounted sight glass with corresponding lighting.

The evaporated water is led via centrifugal dust separators in order to separate the soap dust sucked in and is condensed afterwards in the barometric condenser or surface condenser.

The costs for condensing vapor essentially depend on available cooling water temperature and local conditions of the plant.

3D Model For Continuous Soap Drying Plant